Aluminum Ceramic Heating Element For Molds

Find a huge selection of Aluminum Ceramic Heating Element For Molds from China at GRWAY®. Provide professional after-sales service and the right price, looking forward to cooperation.

Model:7788

Send Inquiry

PDF DownLoad

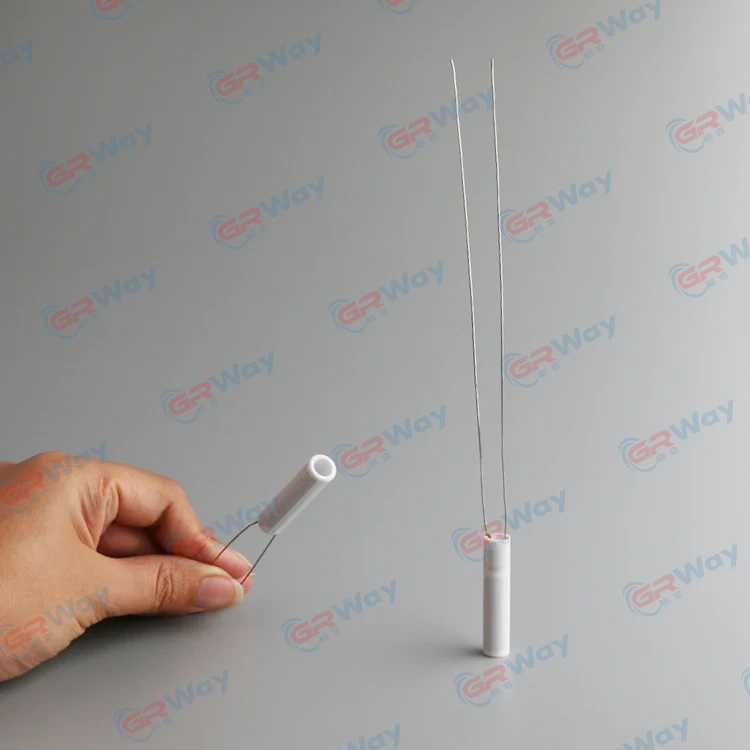

Customized Aluminum Ceramic Heating Element for Molds

GRWAY® Aluminum Ceramic Heating Element For Molds were developed based on ceramic lamination technologies, which are mainly used for automotive and various industrial applications such as soldering iron, kerosene & gas equipment, pellet burner and water heating.

Process of Aluminum Ceramic Heating Element For Molds

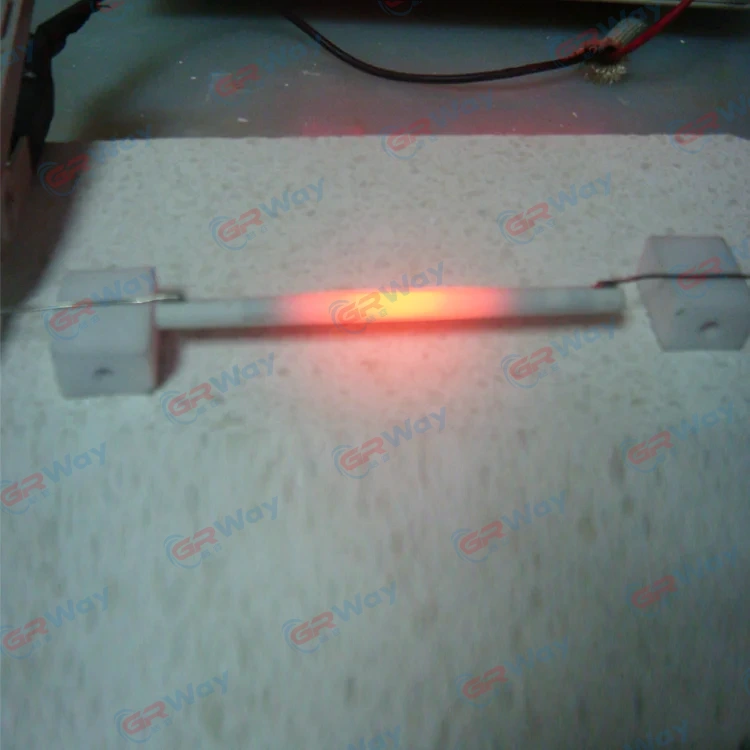

First, painting the high melting point metal (tungsten or molybdenum manganese) paste on to the Al2O3 casting briquette in coordinate to the circuit design, then another layer of sintering additives. After that, repeating the process to build multiple layers. Then, they are sintered together under 1600 °C hydrogen gas environment. Finally, nickel leads are brazed at 800 °C onto the metal end and put on with Teflon sleeve, which make it a MCH heating element.

Internal Heating elements are protected from oxidation due to sintering into one-piece ceramic body structure.

Parameter of Aluminum Ceramic Heating Element For Molds

Aluminum Ceramic Heating Element For Molds Application

The aluminum ceramic heaters are widely used in all kinds of applications nowadays, such as: intelligent bidet seat, electric water heater, medical machine, dryer, electric heating splint, electric iron, vacuum flask, electric cooker.

Packing and Delivery

The suitable packing should be taken to avoid the breakage and contamination during the shipment.

Fast International Express Delivery such as DHL,TNT,FEDEX, UPS ect.

Our Advantage

1.Aluminum Ceramic Heating Element Factory

2.On-line Employees more than 150~200

3.Customization are welcome

4.Heater Month Capacity:550,000 piece

5.Quick Delivery time for already models:1-3 days

6.Free Heater elements Samples are available

FAQ

1.Do you have the products in stock?

Accordingly. Please contact us to confirm.

2.What's your warranty terms?

Generally, 13 month after delivery.

3.Can your products be customized?

Yes, we have a professional R&D team for you service just need to let me know your requirement.

4.How long is the production cycle?

3-35 days

5.What are your terms of payment?

T/T ,Western Union ,Paypal or Credit Card.

6.Do you have a showroom?

Yes, showroom with full range of products.