Products

- View as

Heating Element For Pellet Stove

GRWAY® Heating Element For Pellet Stove,which is MCH process, refers to Metal Ceramic Heater.The main material is 95% AL2O3. It is manufactured by 1650 C high temperature Co-sintered with heating layer printed on the ceramic sheet.

Read MoreSend Inquiry120v Ceramic Heating Element

GRWAY® 120v Ceramic Heating Element were developed based on ceramic lamination technologies, which are mainly used for automotive and various industrial applications such as soldering iron, kerosene & gas equipment, pellet burner and water heating.

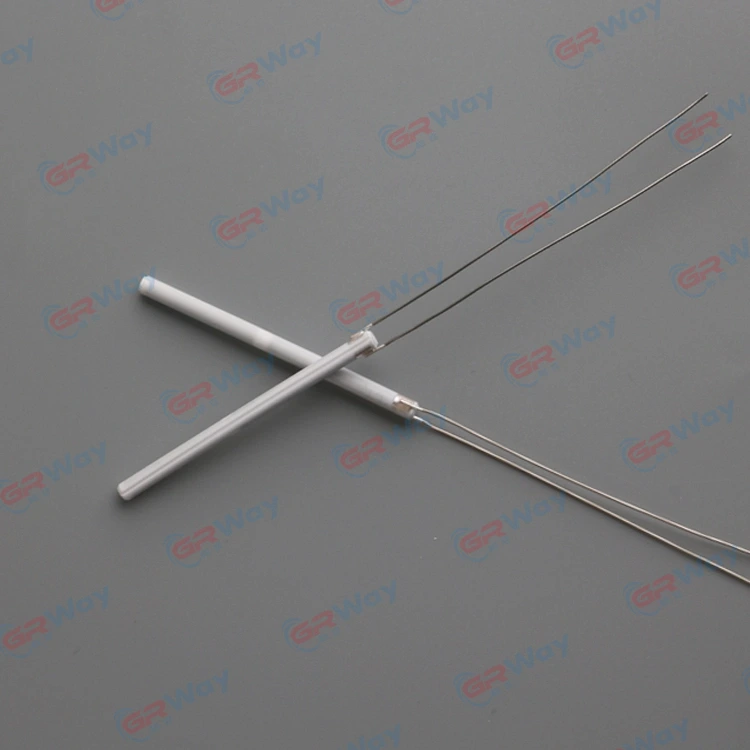

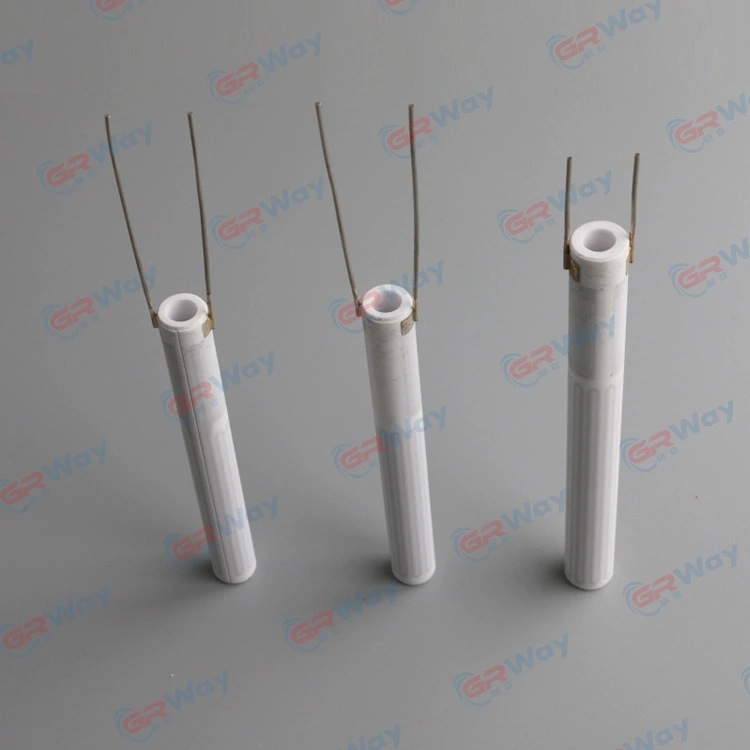

Read MoreSend InquiryMicro Ceramic Heating Element

GRWAY® Micro Ceramic Heating Element were developed based on ceramic lamination technologies, which are mainly used for automotive and various industrial applications such as soldering iron, kerosene & gas equipment, pellet burner and water heating.

Read MoreSend InquiryHeating Element For Hot Water Heater

GRWAY® Heating Element for Hot Water Heater is Ceramic Heater element produced by implementing ceramic lamination processes. Due to the compactness, high power and rapid heating speed .Ceramic Heater can provide higher reliability than ever before. Mainly applications include use as innovative types of heaters in the automotive, medical and semiconductor industries.

Read MoreSend Inquiry12v Heating Element

GRWAY® 12v Heating Element is mainly made of Al2O3,which is manufactured by sintering in high temperature above 1600 deg C with heating layer printed in the ceramic sheet.The ceramic heaters generates heat when an electric current is applied to .It is capable of raising its temperature to 800 deg C within 30 seconds.The metal ceramic heating core has many merit such as excellent resistance,noiselessness,usefulness for every required heat-setting.Mean while this kind of MCH Ceramic Heater contains no harmful materials such as lead,hg,chromium ect.

Read MoreSend InquiryStove Heating Element

GRWAY® Stove Heating Element,which is MCH process, refers to Metal Ceramic Heater.The main material is 95% AL2O3. Stove Heating Element is manufactured by 1650 C high temperature Co-sintered with heating layer printed on the ceramic sheet.

Read MoreSend Inquiry