Soldering Station Heating Elements

Send Inquiry

PDF DownLoad

Soldering Station Heating Elements

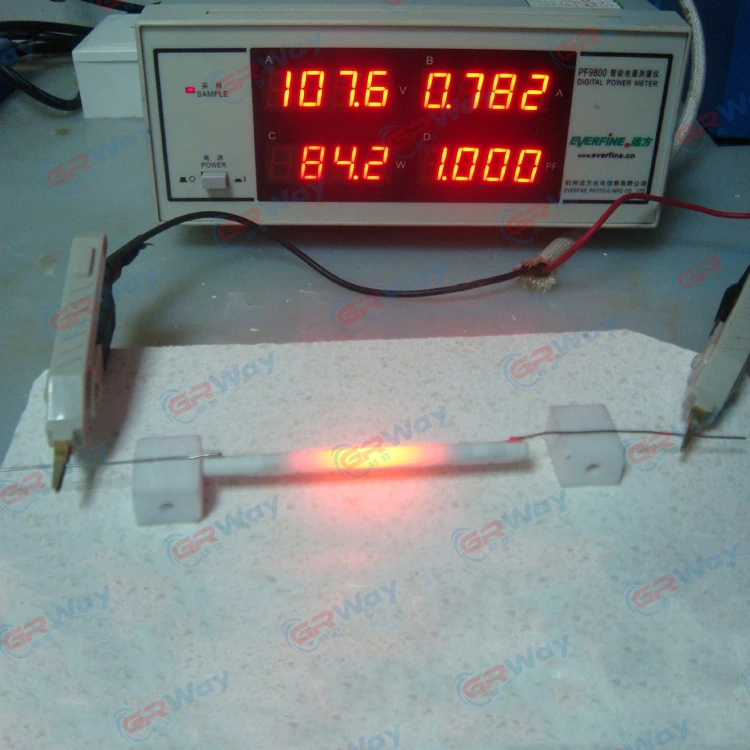

GRWAY® Soldering Station Heating Elements were developed based on ceramic lamination technologies, which are mainly used for automotive and various industrial applications such as soldering iron, kerosene & gas equipment, pellet burner and water heating.

Process of Soldering Station Heating Elements

First, painting the high melting point metal (tungsten or molybdenum manganese) paste on to the Al2O3 casting briquette in coordinate to the circuit design, then another layer of sintering additives. After that, repeating the process to build multiple layers. Then, they are sintered together under 1600 °C hydrogen gas environment. Finally, nickel leads are brazed at 800 °C onto the metal end and put on with Teflon sleeve, which make it a MCH heating element.

Internal Heating elements are protected from oxidation due to sintering into one-piece ceramic body structure.

Parameter limitation of Soldering Station Heating Elements

Application

Electronic cigarette, vaporizers, coffee machine, Intelligent toilet, instant electric kettle, instant water heater, intelligent basin faucet; hair straightener, hair curler, car exhaust oxide sensor, heating for industry device, ultrasonic heating element, mold heater, medical equipment heater ,air heater, small household appliances, etc......

OUR Advantage

1.Factory direct: Professional MCH ceramic heater core manufacturer.

2. Various products: Thousands of already open heater core elements for your choice.

3. Customized according to needs:We are customized according to customer demand, to meet customer needs at any time.

4. Stable quality: Depending on the needs of the user, Our company has been through professional quality system certification, CE certification, SGS audit.

5. Continuous research and development of new products to meet the higher requirements of the client.

FAQ

1. How can I place an order?

You can contact any of our sales person for an order. Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.

2. Can you do the design for us?

Yes. We have a professional team having rich experience in heater design and manufacturing.

Just tell us your ideas and we will help to carry out your ideas into perfect boxes.